某公司700吨薯类酒精废水处理工程设计(含CAD图)(外文翻译,计算说明书21000字,CAD图11张)

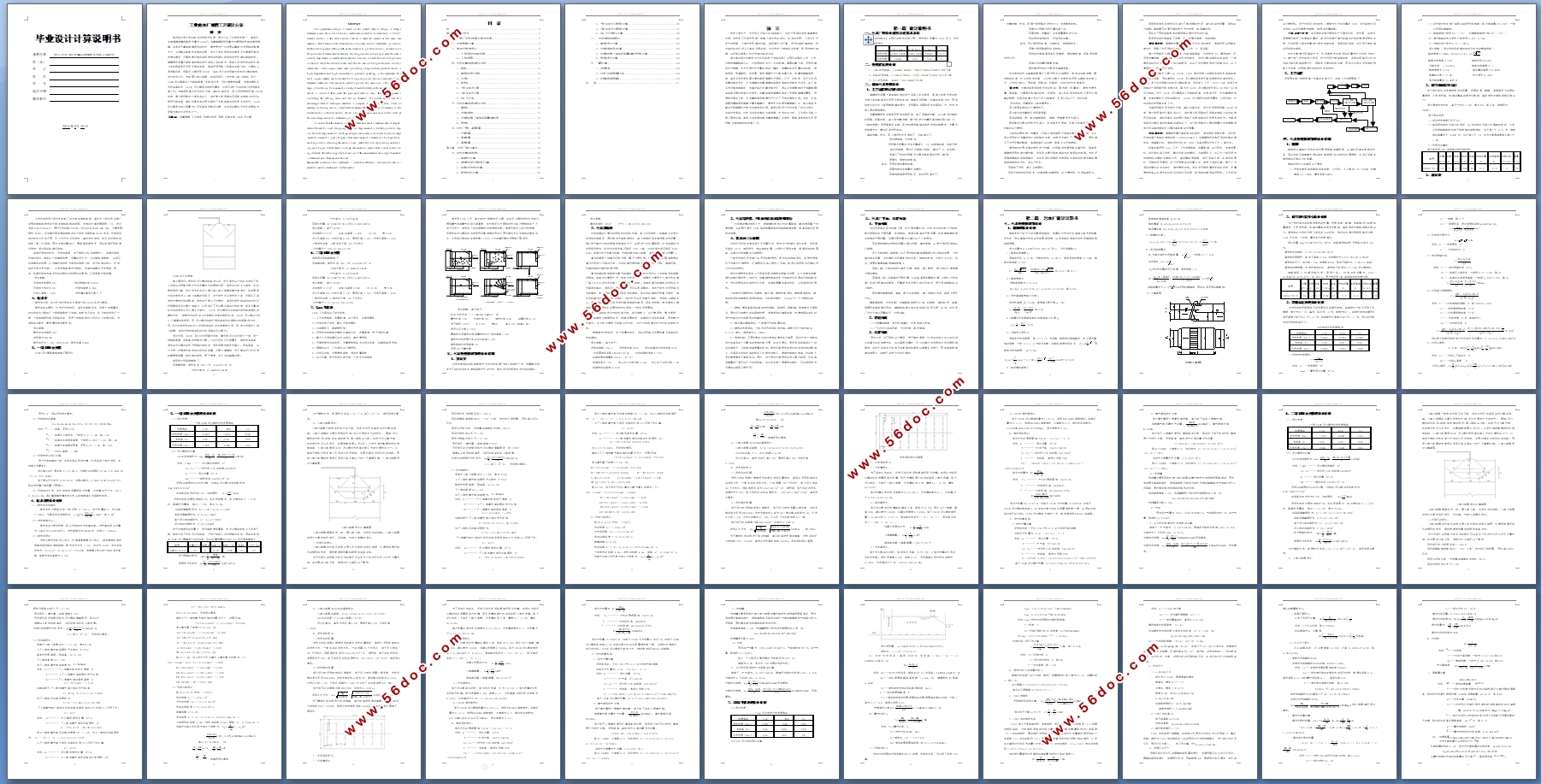

摘 要

本次毕业设计是以相关的资料为依据,设计一座工业废水处理厂,其每日处理酒稿废槽液等废水量为700m3。木薯酒精即用木薯为主要原料所制的食用酒精。但是由于薯类酒精废水的特性,要想更进一步发展以薯类作为原料的酒精生产,必须解决其废水处理的问题,设计人员在废水的处理中不仅要满足排水水质的要求,还要考虑对如何实现废水的资源化利用和沼气资源的高值利用。酒精废水是属于高温高浓度的农产品加工有机废水,基本上说废水中的绝大部分有机物都是可采用生物法处理,普遍采用厌氧—好氧的处理方法,主要核心是厌氧阶段,厌氧反应器采用UASB,UASB是升流式厌氧污泥床反应器的简称,由污泥反应区、气液固三相分离器(包括沉淀区)和气室三部分组成。由于UASB反应器具有工艺结构紧凑,处理能力大,无机械搅拌装置,处理效果好及投资省等特点,UASB 反应器是目前研究最多,应用日趋广泛的新型污水厌氧处理工艺。为确保厌氧出水及沼气产率,减轻好氧负荷,设计采用两级厌氧(UASB)处理,第一级厌氧进行高负荷运行,再经第二级厌氧将可厌氧处理部分的有机物尽可能处理,减轻好氧负荷的同时降低了处理成本并回收更多的沼气。UASB反应器是目前应用最为广泛的高速厌氧反应器,该技术在国内外已经发展成为厌氧处理的主流技术之一。

关键词:木薯酒精 工业废水 资源化利用 厌氧-好氧处理 UASB反应器

Abstract

This graduation design is based on the related data to design a sewage treatment plant, the yield of alcohol wastewater needed to be treat daily is 700m3. Cassava alcohol is the edible alcohol which is made by cassava as the main raw materials. But because of the characteristics of potato alcohol wastewater, in order to further development of the potato as raw material to produce alcohol, we must solve the problem of wastewater treatment, the designers should not only meet the water quality requirement in wastewater treatment, but also consider the use of high value on how to realize the resource waste and the utilization of biogas resources. Alcohol wastewater is the organic waste water processing of agricultural products which is high temperature and high concentration, generally speaking, in the wastewater the most organic matter can be treated by biological process, the universal adoption of treatment methods is the anaerobic-aerobic process, the main core is the anaerobic stage, it use the up flow anaerobic sludge blanket(UASB) as the anaerobic reactor , which is consist of three parts the gas-liquid reaction zone, three-phase separator (including the settling zone) and the air chamber. The UASB reactor has the advantages that its technique structure is compact, it has large capacity, it has no mechanical stirring device, is has better treatment effect and low investment, so the UASB reactor is studied mostly, which is becoming more and more widely used as the new sewage anaerobic treatment process.

To ensure that the anaerobic yielding water and aerobic methane rate of output, reduce the aerobic load , designing to use two stage anaerobic (UASB) process to dispose, the first stage anaerobic working at high load operation, followed by second stage anaerobic anaerobic ,part of organic that can be anaerobic treated will be disposed as more as possible, reduceing the aerobic load , reduce the cost of processing and recycling more biogas. UASB reactor is a high rate anaerobic reactor that is most widely using currently, the technology has become one of the mainstream technology of anaerobic treatment at both home and abroad.

Keywords: cassava alcohol wastewater / industrial effluent / resources utilization / anaerobic aerobic treatment / UASB reactor

一、污水厂的设计规模及进出水水质

设计的内容为工业园区的废水处理工程,原水设计水量为700 m3/d,进出水水质如表所示:

CODcr(mg/L) BOD5(mg/L) SS(mg/L) PH

原水水质 40000-50000 20000-25000 40000 4-5

出水水质 2000 500 100 7

二、处理程度的计算

1、CODcr的去除率:[(40000~50000)-2000]/(40000~50000)=95%~96%

2、BOD5的去除率:[(20000~25000)-500]/(20000~25000)=97.5%~98%

3、SS的去除率:(40000-100)/40000=99.8%

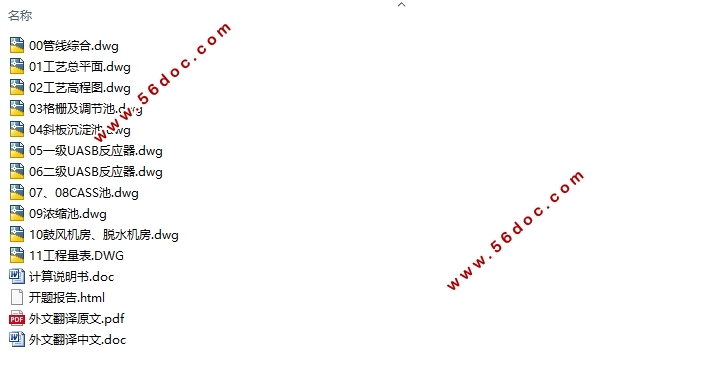

目 录

前 言 5

第一篇 设计说明书 6

一、 污水厂的设计规模及进出水水质 6

二、处理程度的计算 6

三、城市污水处理设计 6

1、工艺流程的比较与选择 6

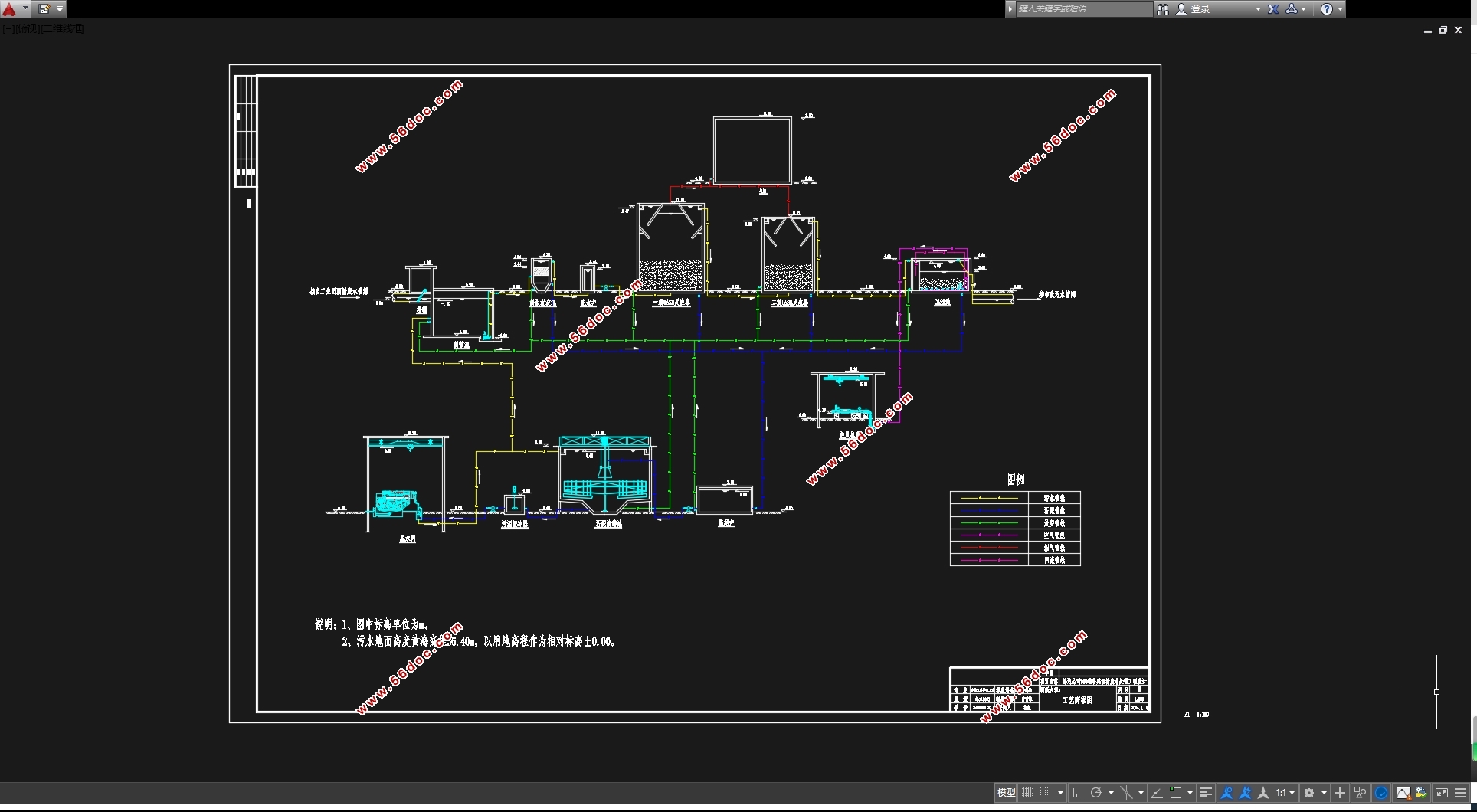

2、工艺流程图 9

四、污水处理构筑物的设计说明 9

1、格栅 10

2、集水井和提升泵房 10

3、初沉池 11

4、配水井 11

5、一级UASB反应器 11

6、二级UASB反应器 13

7、CASS生化池 13

五、污泥处理构筑物的设计说明 14

1、集泥井 14

2、污泥浓缩池 15

3、污泥缓冲器、PAM加药装置和螺杆泵 16

4、脱水间 16

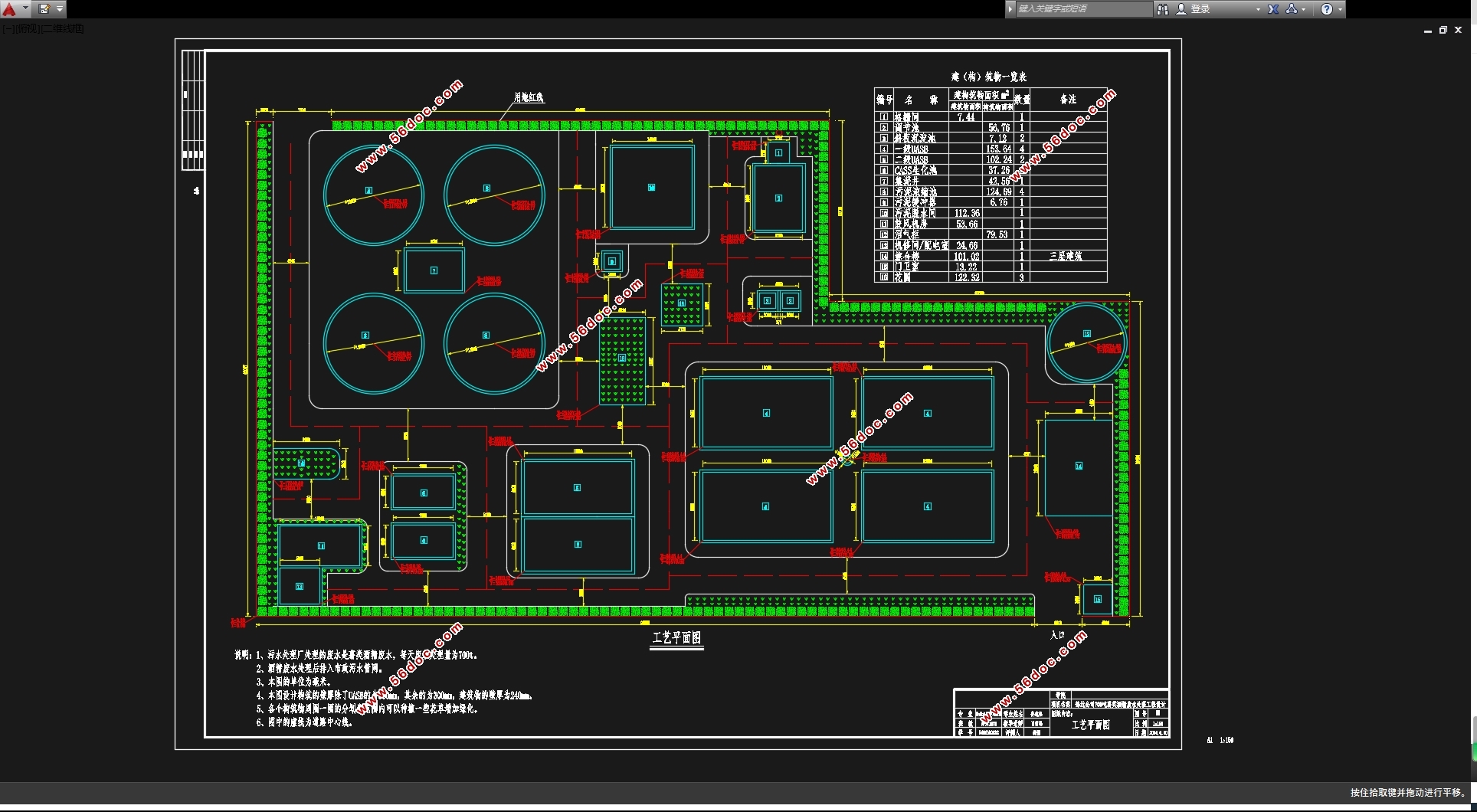

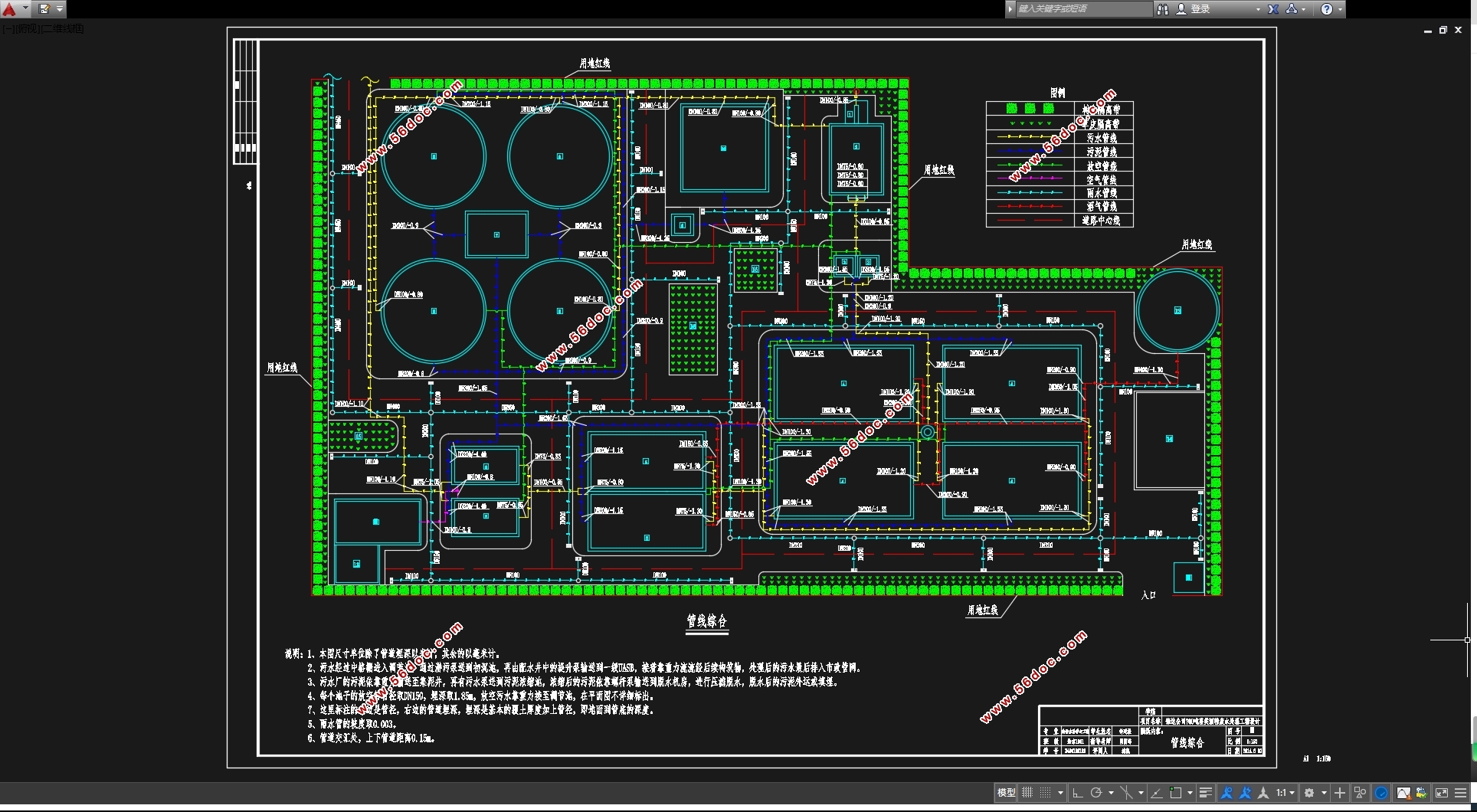

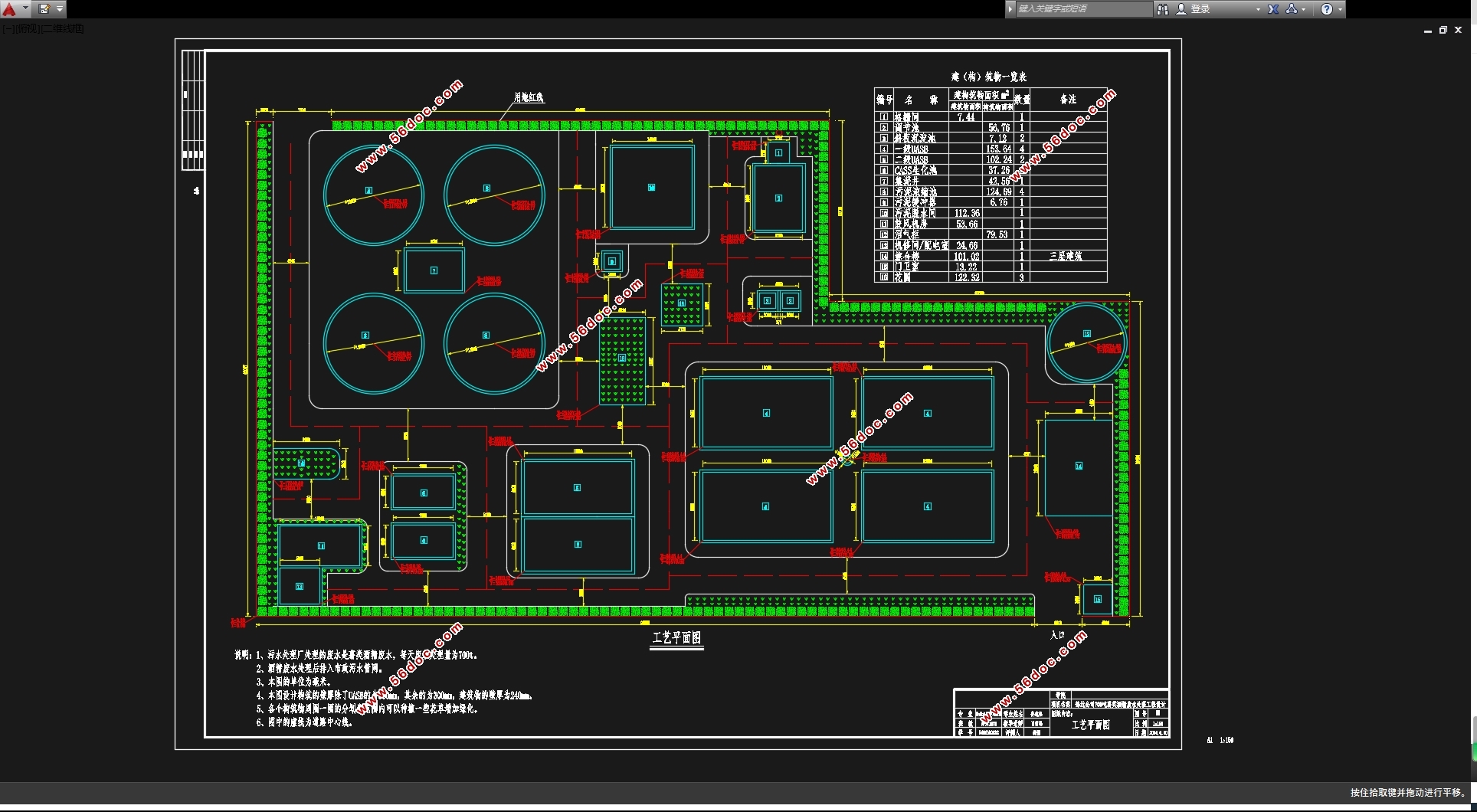

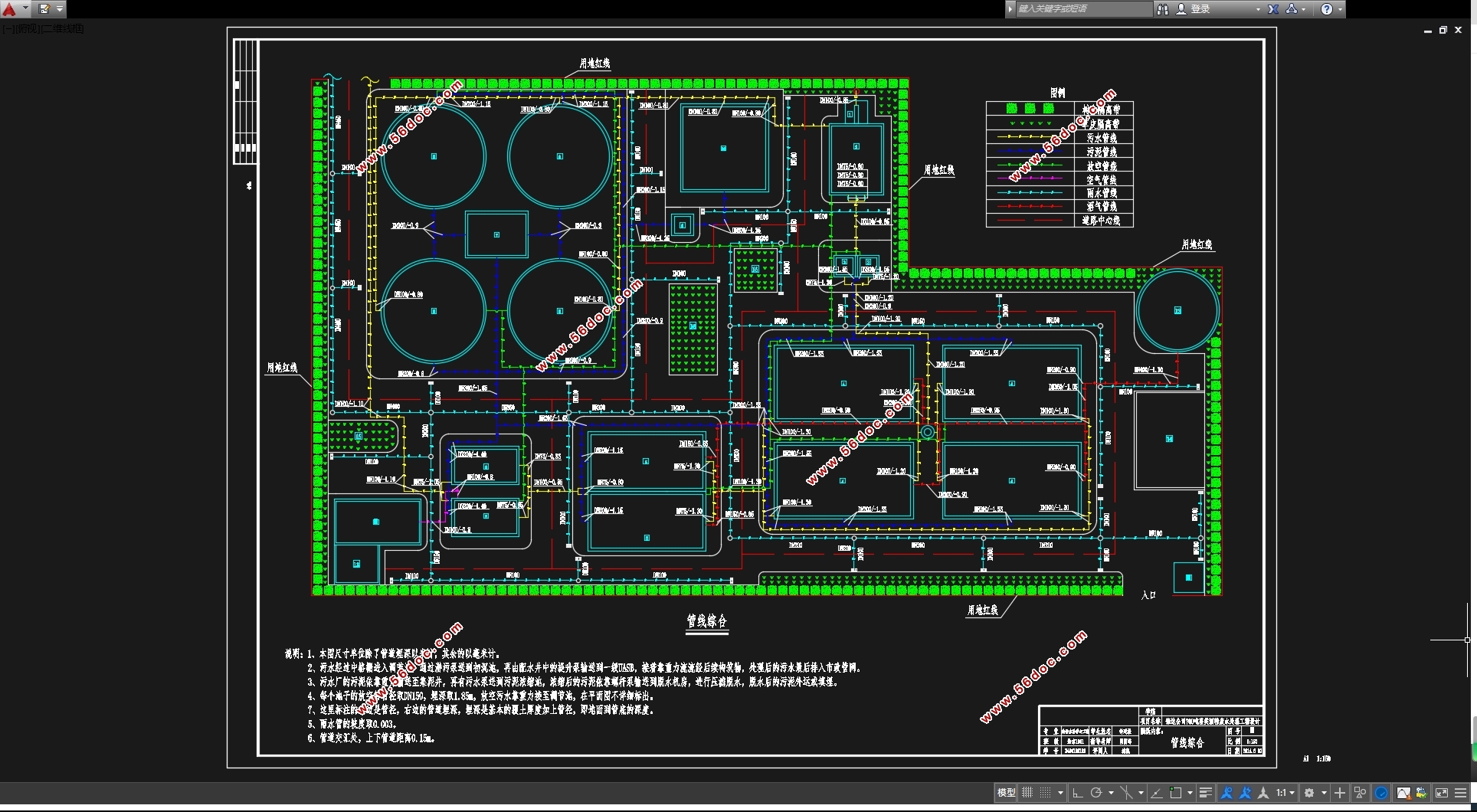

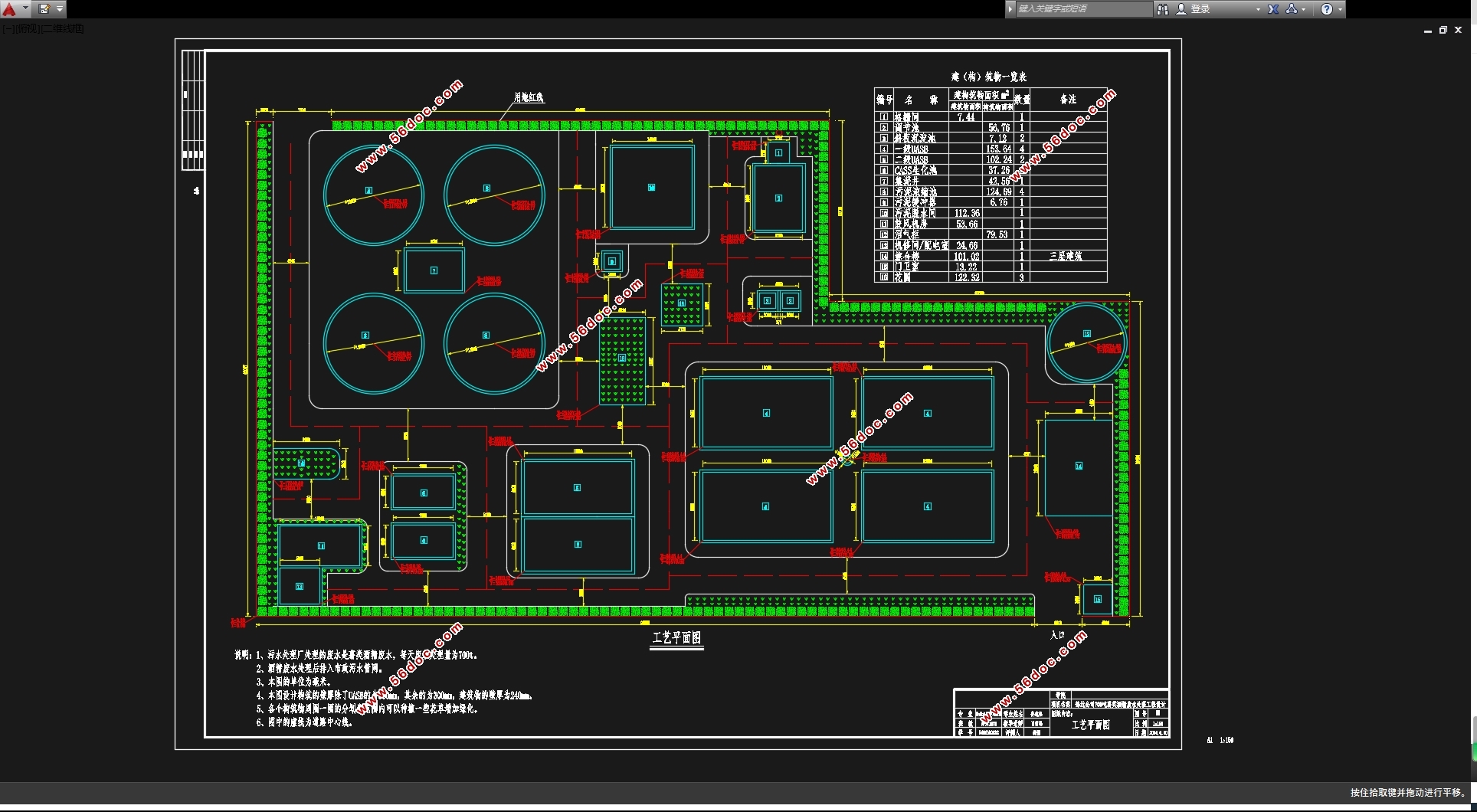

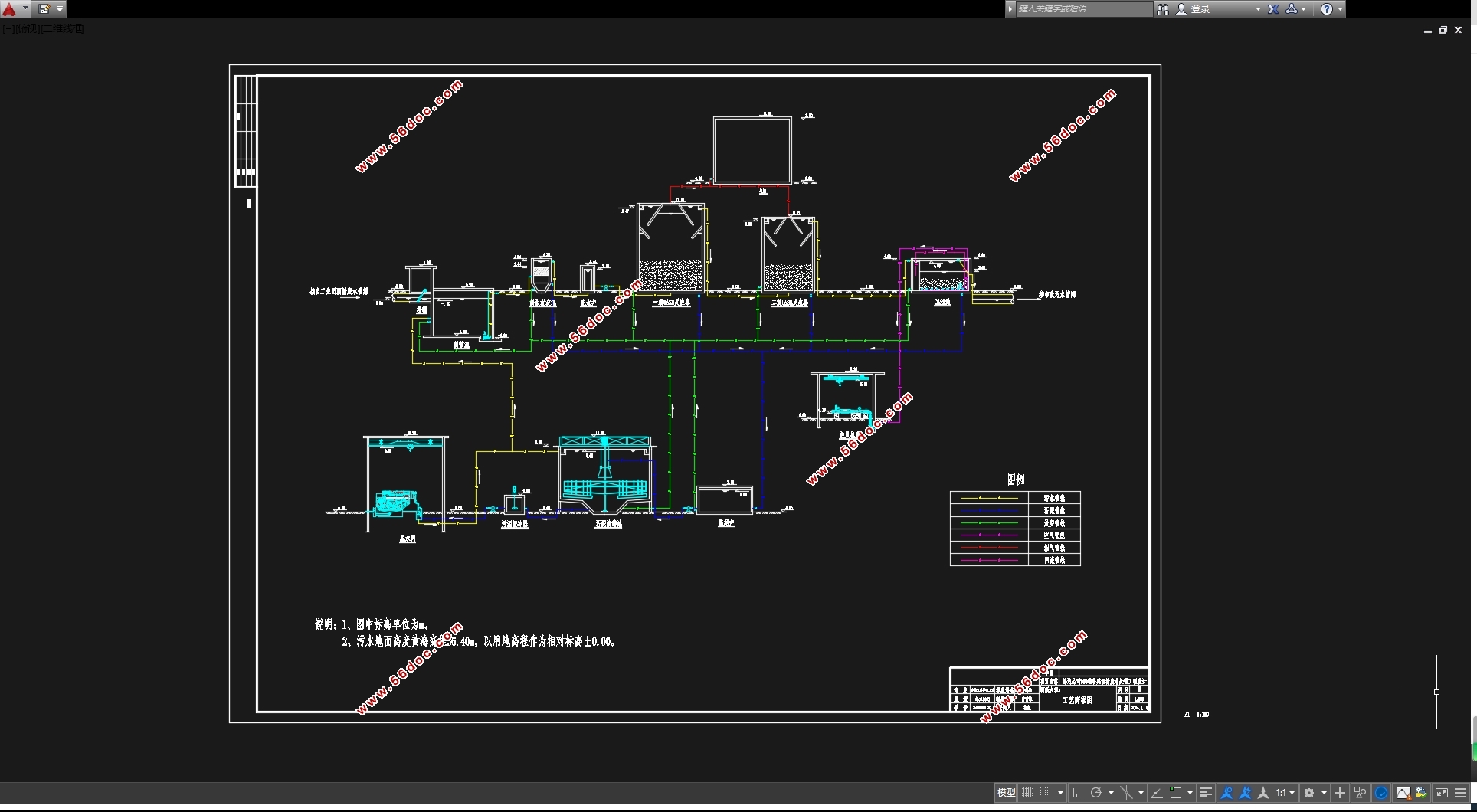

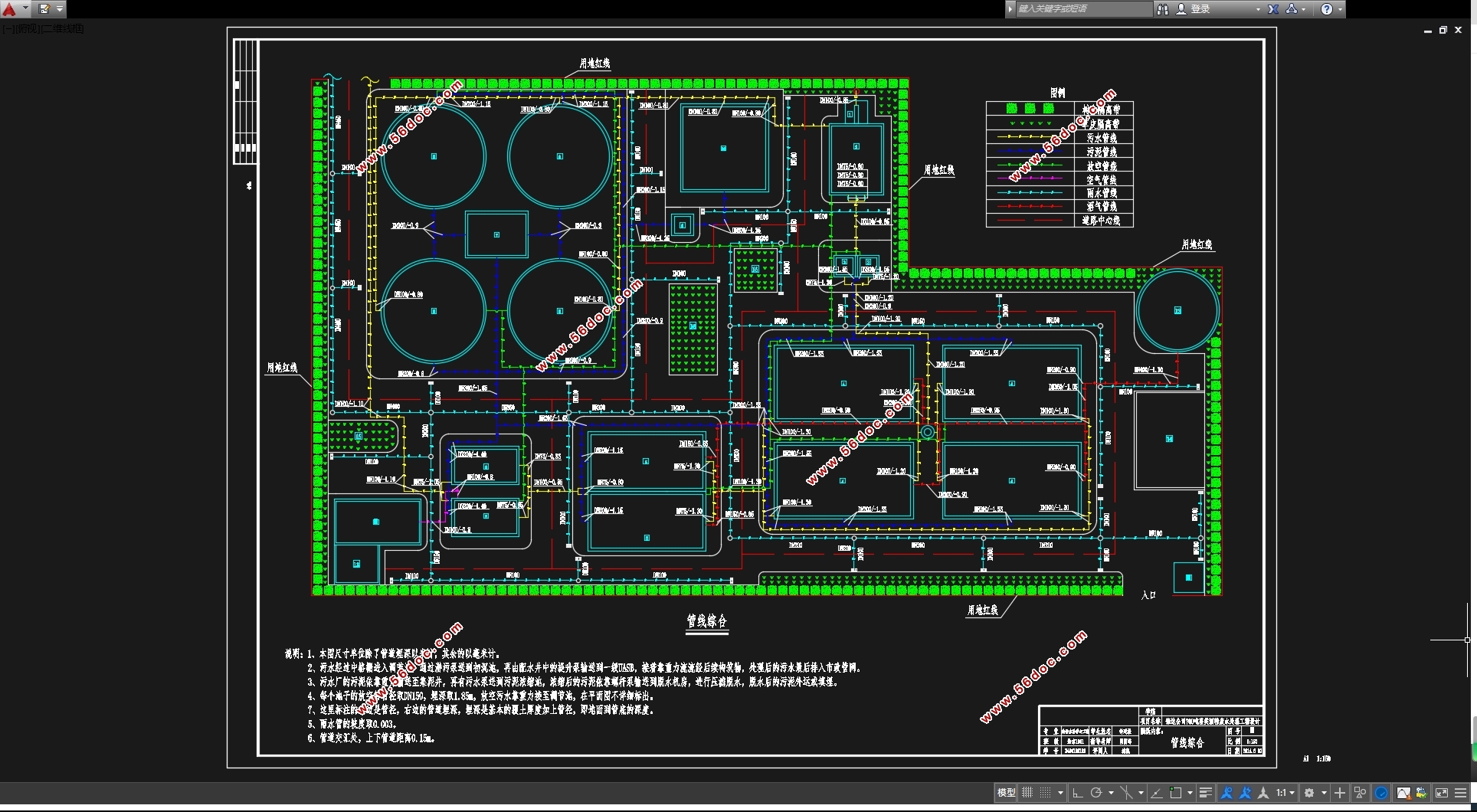

六、污水厂平面、高程布置 17

1、平面布置 17

2、管道布置 17

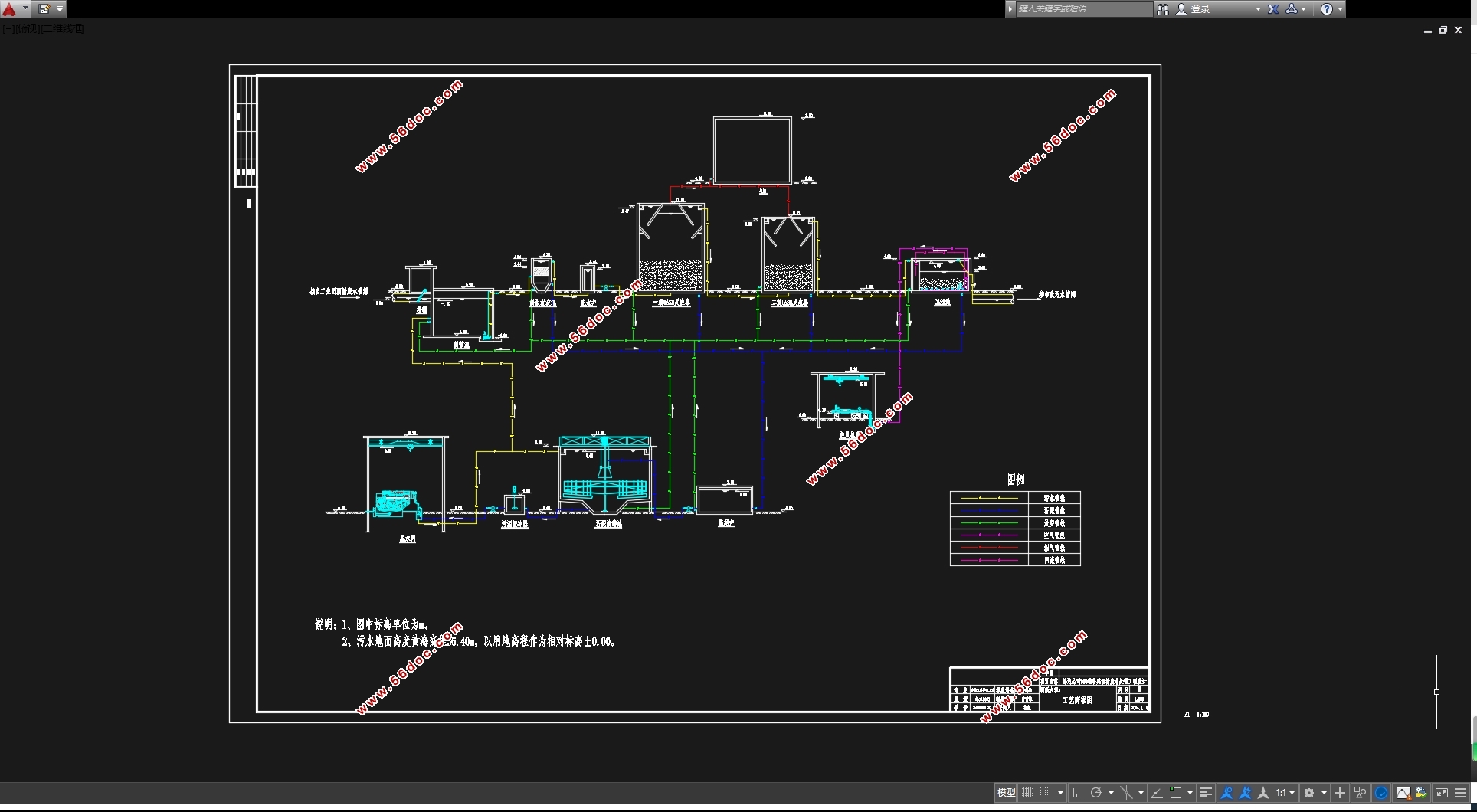

3、高程布置 17

第二篇 污水厂设计计算书 18

七、污水处理构筑物设计 18

1、格栅设计计算 18

2、调节池与提升泵房设计计算 20

3、斜管初沉池设计计算 20

4、配水井设计计算 22

5、一级UASB反应器设计计算 23

6、二级UASB反应器设计计算 31

7、CASS生化池设计计算 38

八、 污泥处理构筑物设计 46

1、集泥井设计计算 46

2、污泥浓缩池设计计算 46

3、污泥缓冲器、PAM加药装置和螺杆泵设计计算 49

4、脱水间设计计算 49

九、 高程计算 49

1、选用管道 49

2、污水厂的高程布置方法 49

3、各构筑物高程确定 50

总 结 51

|