智能齿距测量仪设计(含CAD图,CAXA图)(课题申报表,任务书,开题报告,中期检查表,论文说明书9600字,CAD图纸5张,CAXA图纸5张)

摘 要

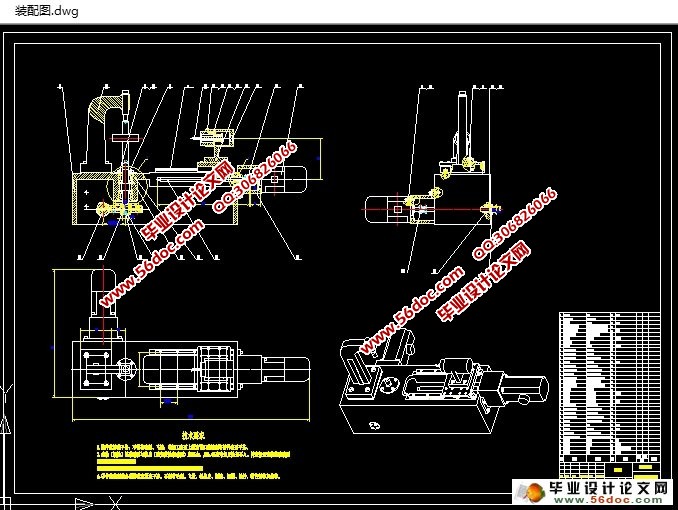

本课题涉及内容为智能齿轮齿距误差测量仪的研究及其设计。在对现今各种齿距误差测量仪进行研究后,本课题在小型、经济方面着手,设计出适合中小形齿轮齿距误差的测量仪器。其特点在于体积小,测量方便,有利于节省空间及使用方便。

本课题实现了单个及多个齿距的误差测量,若对软件部分进行 开发还可测量齿形,齿廓误差等,具有可扩展性。设计中包括机械部分设计和电子测控部分设计及软件的开发。在稳定精度的基础上,机械部分尽量做到了结构简单,以减少积累误差及降低成本。在智能方面,采用单片机系统,实现了自动数据采集,自动测量,自动数据处理,自动显示及打印输出测量结果的“流水”化测量过程,可节省人力及测量时间。在计算方面参考了国内外众多先进的 研究成果,结合本课题特点,选用了相对法计算单个齿距误差,多个齿距累积误差具有简单易行的特点。

本课题说明书在最后对仪器的测量及工作环境做出了经济可行性及环境分 析,本设计产品具有的占地空间小,制造成本低及操作简单,智能测量等的一 系列特性非常适合小型企业中,中小型零件批量生产的需要。除此之外本设计 产品运转噪音低,无污染。综合上述优点本设计产品具有极好的市场前景。

关键词: 齿距误差; 齿轮; 测量仪

Abstract

The research and design of the intelligent gear tooth distance error measuring instrumentt are involved in this thesis.After the study of the present error measuring instrument, the paper designs the measuring instrument for the gear tooth distance error of the middle and middle gears.. Its characteristics lie in small size, convenient measurement, convenient for saving space and easy to use..

The error of single and multiple pitch measurement is realized, and if the software part is developed, it can measure tooth profile, tooth profile error, etc.. Design and development of the design and software of the design and the electrical sub measurement and controlling parts of the design and the electrical sub measurement and control system. On the basis of the stability accuracy, the mechanical part is as far as possible to make the structure simple, in order to reduce the accumulation error and reduce the cost. In the aspect of intelligence by SCM system, realize the automatic data collection, automatic measurement, automatic data processing, automatic display and print the measuring results of "flowing water" measurement process, save manpower and time measurement. In terms of computation with reference to numerous domestic and foreign advanced research results, combined with the subject characteristics, selection of the least square method is used to calculate a single tooth pitch error, the choice of relative method for measuring a plurality of teeth cumulative pitch error has the characteristics of simple.

This topic statement at the end of instrument measurement and working environment make the economic feasibility and environmental analysis, with the design of products covers an area of small space, manufacturing cost is low and the operation is simple, intelligent measurement, such as a series of characteristic, and is very suitable for small and medium enterprises, small and medium-sized zero batch production. In addition to the design of the product operation noise is low, no pollution. The advantages of this design have excellent prospects for the market..

Keyword: Tooth distance error ; gear ;measuring instrument

目 录

摘 要 I

Abstract II

目 录 III

绪 论 1

1 齿距误差测量的理论基础 3

1.1 齿轮齿距偏差相关概念 3

1.1.1 齿轮单个齿距偏差(fpt) 3

1.1.2齿距累积偏差 3

1.1.3 齿距累积总偏差(Fp) 4

1.2测量原理 4

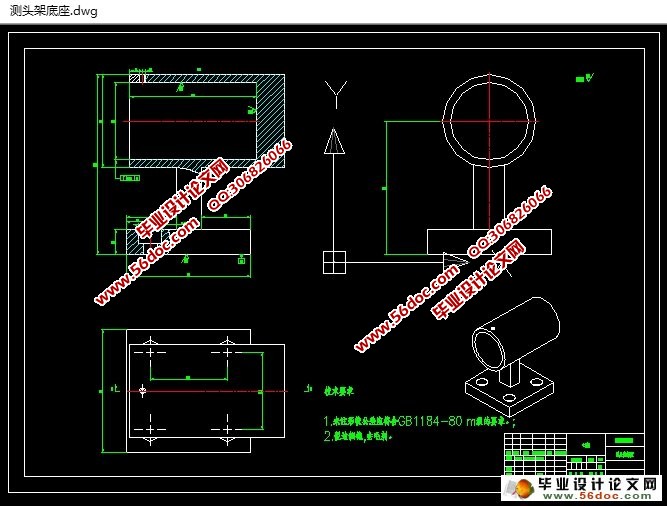

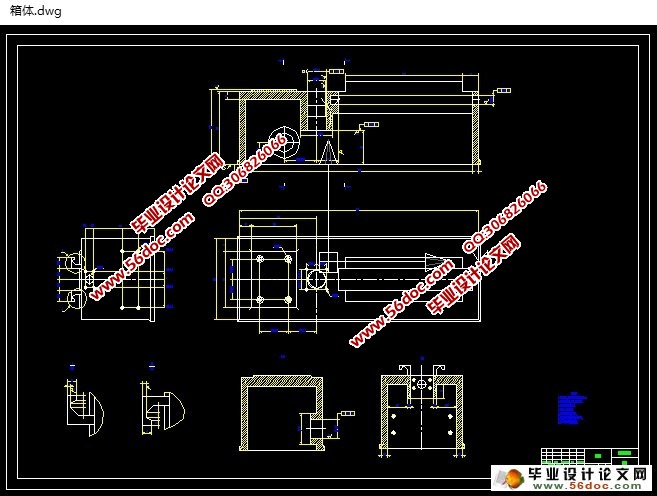

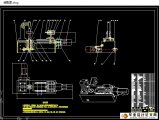

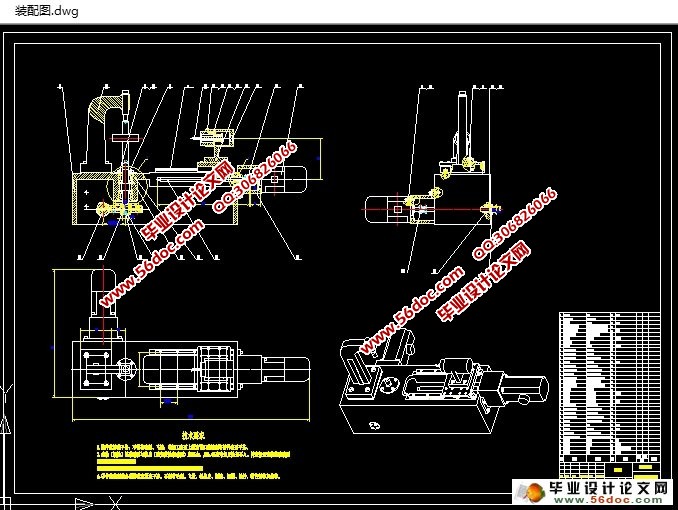

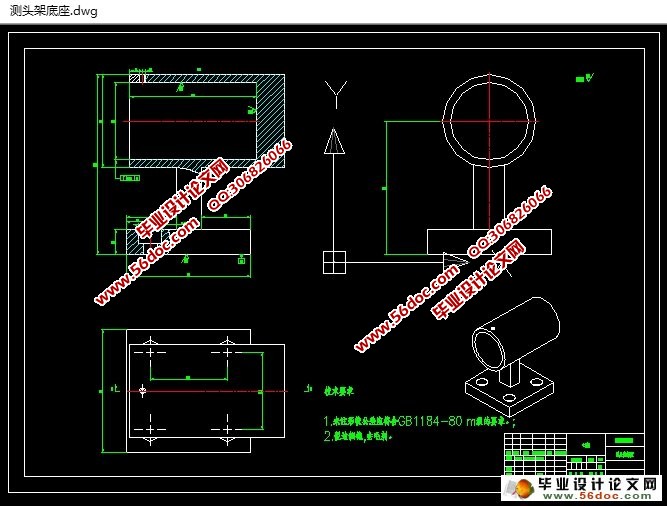

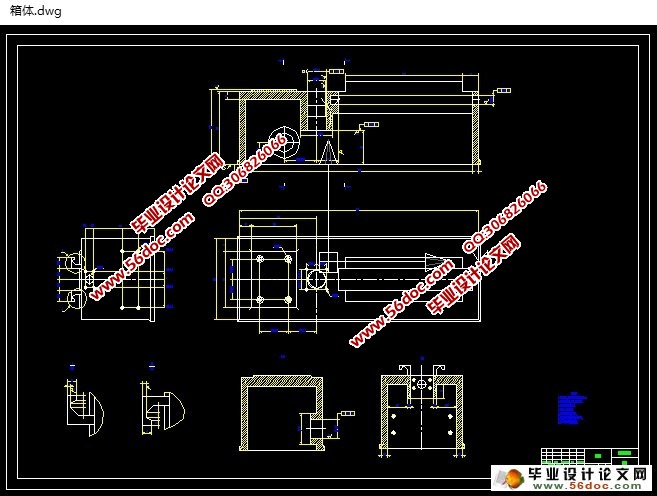

2智能齿距误差测量仪的机械系统的设计 7

2.1 步进电动机的选择 7

2.2 主轴传动系统的设计 8

2.2.1丝杠的设计 8

2.2.2 蜗轮蜗杆的设计 8

3智能齿距误差测量仪的单片机部分设计 11

3.1 单片机硬件系统的设计 11

3.1.1 单片机系统的整体设计 11

3.1.2 信号采集模块设备选择 11

3.1.3 信号调整模块的设计 12

3.1.4 步进电动机驱动电路设计 13

3.2 单片机软件系统的设计 14

3.2.1 主程序的程序 14

3.2.2读入 A/D 数据程序 14

3.2.3 数字滤波程序 15

3.2.4 键盘扫描输入程序 16

3.2.5 步进电机驱动控制程序 16

3.2.6 打印机输出程序 16

4 经济可行性及环境分析 18

5 结论 21

致 谢 22

参考文献 23

|