汽车盖板冲裁模设计(设计说明书18000字,CAD图纸13张)

摘 要

冲压工艺是塑性加工的基本方法之一。它主要用于加工板料零件,所以有时也叫板料冲压。冲压不仅可以加工金属板料,而且也可以加工非金属板料。冲压加工时,板料在模具的作用下,于其内部产生使之变形的内力。当内力的作用达到一定程度时,板料毛坯或毛坯的某个部位便会产生与内力的作用性质相对应的变形,从而获得一定的形状、尺寸和性能的零件。

冲压生产靠模具与设备完成加工过程,所以它的生产率高,而且由于操作简便,也便于实现机械化和自动化。

冲压产品的尺寸精度是由模具保证的,所以质量稳定,一般不需再经过机械加工便可使用。

冲压加工一般不需要加热毛坯,也不像切割加工那样大量切削材料,所以它不但节能,而且节约材料。冲压产品的表面质量较好,使用的原材料是冶金工厂大量生产的轧制板料或带料,在冲压过程中材料表面不受破坏。

因此,冲压工艺是一种产品质量较好而且成本低的加工工艺。用它生产的产品一般还具有重量轻且刚性好的特点。

我国考古发现,早在2000多年前,我国已有冲压模具被用于制造铜器,证明了中国古代冲压成型和冲压模具方面的成就就在世界领先。1953年,长春第一汽车制造厂在中国首次建立了冲模车间,该厂于1958年开始制造汽车覆盖件模具。我国于20世纪60年代开始生产精冲模具。在走过了温长的发展道路之后,目前我国已形成了300多亿元(未包括港、澳、台的统计数字,下同。)各类冲压模具的生产能力。

冲压模具行业发展现状及技术趋势。

关键词:模具 冲压工艺 材料

Abstract

Blunt press a craft is one of the basic methods that the Su process.It is mainly used for processing plank to anticipate spare parts, so sometimes also call the plank anticipate blunt press.Blunt press can not only process metals plank to anticipate, but also can also process nonmetal plank to anticipate.Blunt press to process, the plank anticipates under the function of molding tool and make it transform at its internal creation of inside dint.When inside the function of dint attain certain degree, the plank anticipate a certain part of semi-finished product or semi-finished product and then will produce with inside the function property of dint opposite in response to of transform, acquire certain shape, size and the spare parts of function thus

Blunt press to produce to be processed process by molding tool and equipments completion, so it of rate of production Gao, and because of operation simple, also easy to realization mechanization and automation.

Blunt press the size accuracy of product is promise by the molding tool of, so quality stable, generally doing not need to through machine process again then can use.

Blunt press to process generally don't need to heat semi-finished product, also be unlike to incise to process to so and in great quantities slice to pare material, so it not only economizes on energy, but also economize material.Blunt press the surface quality of product better, the original material of usage is a metallurgy factory mass production of the Ya system plank anticipate or take to anticipate and the material surface is free from breakage in bluntly ran over the distance.

Therefore, it ising blunt to press a craft be a kind of product quality better and the cost lowly process a craft.Use the product that it produce generally still has the weight light and rigid and good characteristics.

Our country study of ancient relics to discover, as early as more than 2000 year agos, our country already have blunt press a molding tool to be used for to make bronze utensils, prove Chinese ancient times blunt press to model with blunt press an achieve of molding tool to lead in the world.Grow spring in 1953 the first car manufactory built up a blunt mold car for the very first time in China and that factory started make a car to overlay a molding tool in 1958.The our country starts produce Jing a blunt molding tool in 60's in 20 centuries.Walk through grow of development road after, the our country has already become more than 100000000 dollars 300 currently(DO not include the statistics of harbor, Ao, pedestal, under together.)Every variety is blunt to press the production ability of molding tool.

Blunt press the development present condition of the molding tool profession and technique trend.

Keyword: Molding tool Blunt press a craft Material.

客户要求: 1、设计一付复合模,要求操作维修方便;

2、模具总寿命不低于60万冲次,刃磨一次寿命不低于15000冲次。

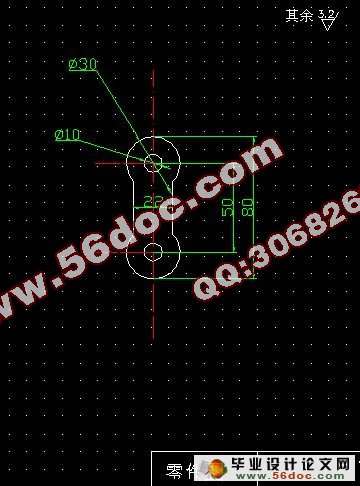

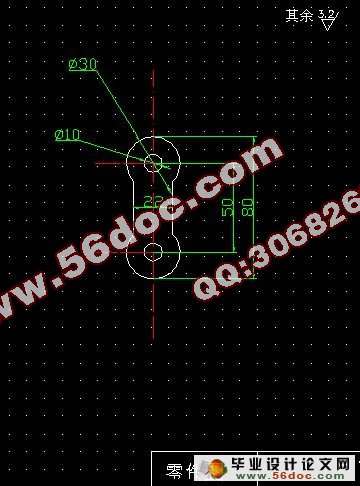

工件名称:夹头垫片

生产批量:成批

材 料: 20钢

料 厚:1mm

目 录

第一章 引言 1

1.1、课题简介: 1

1.2.1选题的依据(来源) 1

1.2.2选题的背景 2

1.2.3选择课题目的意义 3

1.3、实例分析 8

1.4、零件客户要求 9

第二章 冲压工艺方案的选择 10

2.1、加工方案比较 10

2.1.1机械加工法 10

2.1.2、使用冲压模 10

2.1.3材料的选择 12

第三章 工艺与模具的设计 15

3.1冲压工艺与模具设计 15

3.1.1、工艺可行性的判别 15

3.1.2、零件冲裁工艺性分析 15

3.2确定冲压工艺方案 16

3.3、模具结构的确定 16

3.4排样、计算条料宽度及确定步距 17

3.5.计算冲压力 17

3.6.确定模具压力中心 19

3.7.冲模刃口尺寸及公差的计算 19

3.8.确定各主要零件结构尺寸 21

3.9.压力机的选用 22

第四章 绘制部分图形及其工艺 24

4.1. 设计并绘制总图、选取标准件 24

4.2、 绘制部分非标准零件图 25

4.3、模具的加工工艺过程 28

第五章 致谢辞 35

参考文献 36

|