螺纹盖注射模设计与制造(CAD,Proe三维)(任务书,论文说明书6000字,CAD图13张,Proe三维图)

摘 要

注射成型是一个将熔融的塑料压入模具型腔的过程。一旦塑料冷却,塑料件即可脱模。注射成型是用于制造零件一种比较新的方法,它主要包括六个步骤,即锁模、注射、保压、冷却、开模以及脱模。

由于成型效率较高而可大批量生产、可成型各种不同使用性能的热塑性材料、可成型带有螺纹、侧向凹陷和侧孔的塑件以及较大的薄壁件等诸多优点,注塑模已广泛用于生产各种塑件。

注射模技术的持续发展对设备的要求越来越高。注塑模具的合理设计是注塑成败的关键。一般来说,高效生产注塑成型件主要取决于注塑模具,而模具的耐用性则取决于日常的维护和保养。

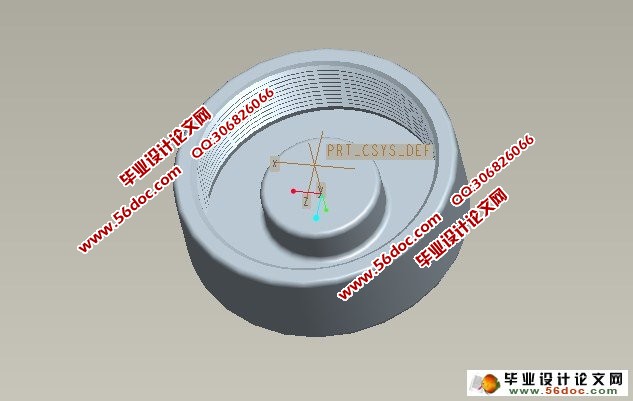

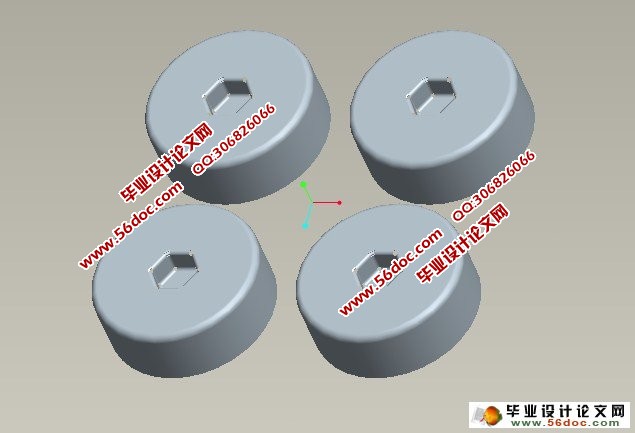

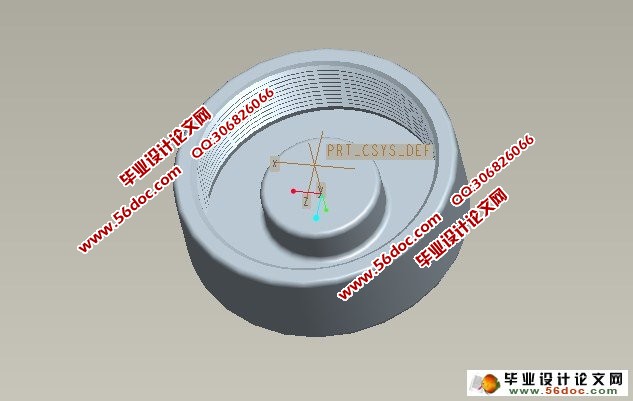

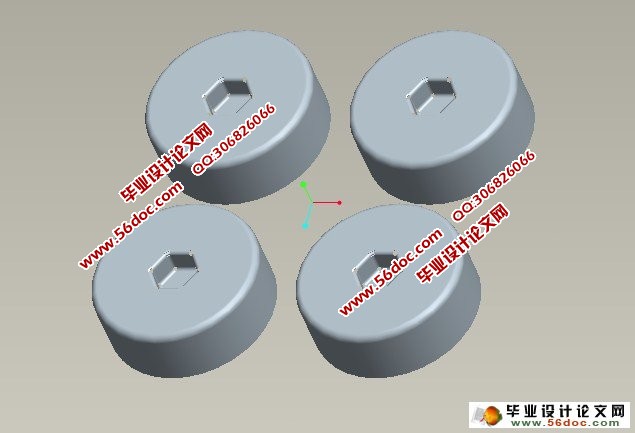

螺纹盖注塑模。因为有螺纹和内六角的存在,为保证精度,在模具设计和制造上要求有精密的定位措施和良好的加工工艺。

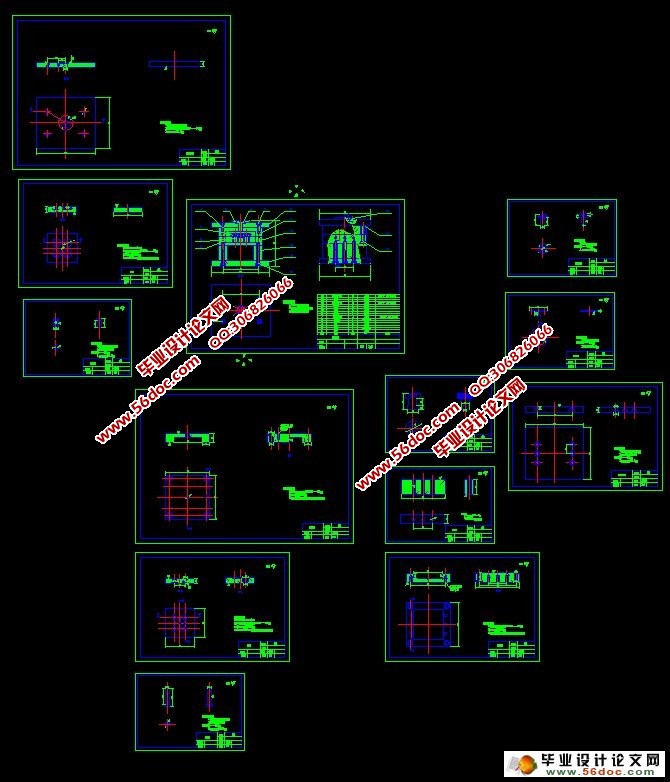

本文的主要内容包括:塑件的工艺性分析;成型设备的选择;塑料模设计、零件尺寸计算以及模具主要零件加工工艺规程的编制等。

关键词

螺纹盖;注射模;一模多腔;模具设计

Abstract

Injection molding is the process of forcing melted plastic into a mold cavity. Once the plastic has cooled, the part can be ejected. It is a relatively new way to manufacture parts. There are six major steps in the injection molding process, i.e, clamping mold, injection, dwelling, cooling, mold opening and ejection.

Nowadays, injection molding has been used to produce plastic parts widely, for its such advantages as high molding efficiency possible for mass-production, wide choice of thermoplastic materials providing a variety of useful properties as well as possible to mold threads, undercuts, side holes, and large thin sections.

The continuous development of injection molding technology demands injection machine. The most important problem in the process of injection molding is undoubtedly the correct design of the injection mold. Generally, efficient production of injection molded parts depends primarily on the injection mold. However, durability of the molds is determined by their daily care and treatment..

Threaded cover injection mold. Because a thread and hex existence, to ensure accuracy, in the mold design and manufacturing requirements have precise positioning measures and good processing technology.

The main contents of this paper are following: processing analysis of plastic part, selection of injection machine, mould design, calculation of part dimension and scheduling of technological process of the main parts.

Key words

Threaded cover; Injection mould; A mold cavity; Mold design

目 录

摘 要 1

Abstract 2

引 言 5

1. 选题背景、研究意义及文献综述 6

1.1 选题背景 6

1.2 研究意义 6

1.3 我国塑料模的现状 6

2、塑件的工艺性分析 7

2.1 塑件的尺寸精度分析 8

2.2 塑件表面质量分析 8

2.3 塑件的结构工艺性分析 8

3、确定成型设备选择与模塑工艺规程编制 8

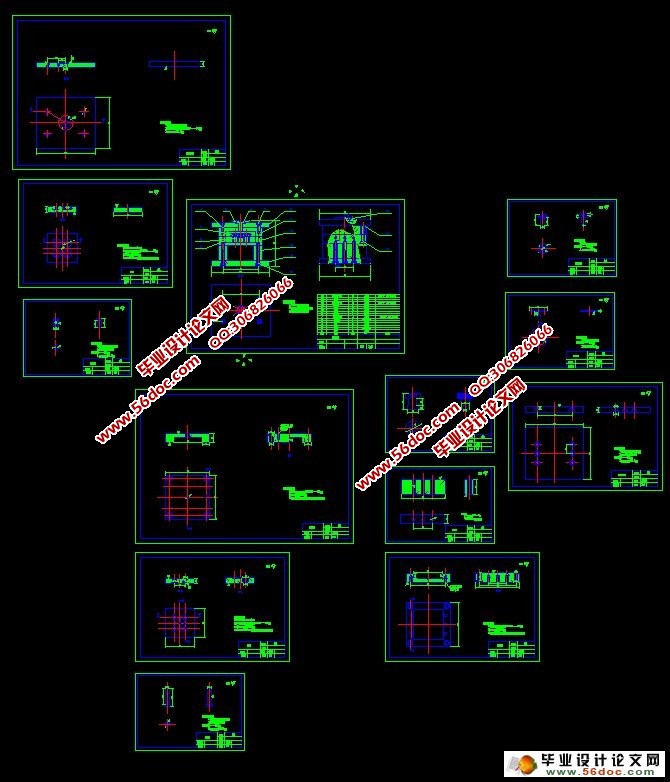

4、注射模的结构设计 10

4.1 分型面的选择 10

4.2 型腔数目的确定及型腔的排列 11

4.3 浇注系统的设计 11

4.4 型芯与型腔的结构设计 12

4.5 推出方式的选择 12

4.6 活动箱块的设计 12

5、注射模有关零件设计 13

5.1 模具总装图 13

5.2 模具零件的设计 14

6、注射机有关参数的校核 18

6.1 闭合高度的确定和校核 18

6.2 开模行程的校核 19

7、注射模主要零件加工工艺规程的编制 19

7.1 型腔固定板的加工工艺过程 19

7.2浇口套的加工工艺过程 20

设计总结 21

致 谢 22

参考文献 23

|