流量为105t/h固定管板式换热器(含CAD零件装配图)(设计说明书13500字,CAD图纸8张)

摘要

管壳式换热器作为固定管板式换热器的一种具有代表性的结构,是当前应用较为广泛的一款换热器。这款换热器拥有诸多特点:结构简易,紧凑,适用面广泛,安全系数高,选料面广泛,低成本,换热表面清洗极方便。由于固定管板式换热器可以经受比较高的操作温度和压力,所以这类换热器占有极大优势在各类高压高温和大型换热器中。[1]

换热器简单说是具有不同温度的两种或两种以上流体之间传递热量的设备。在工业生产过程中,进行着各种不同的热交换过程,其主要作用是使热量由温度较高的流体向温度较低的流体传递,使流体温度达到工艺的指标,以满足生产过程的需要。此外,换热设备也是回收余热,废热,特别是低品位热能的有效装置。[2]

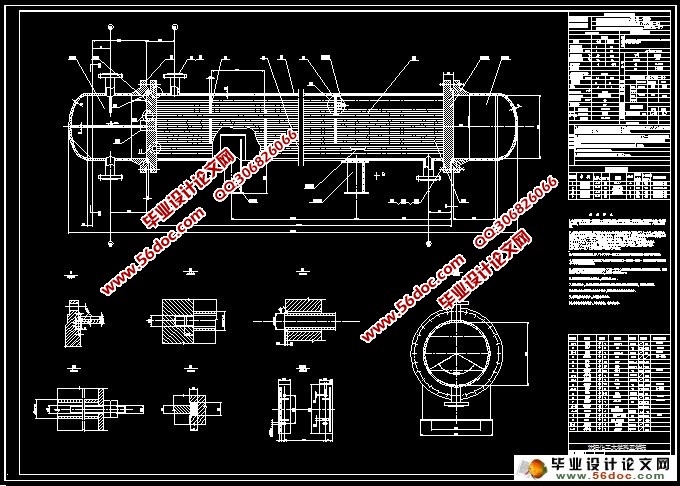

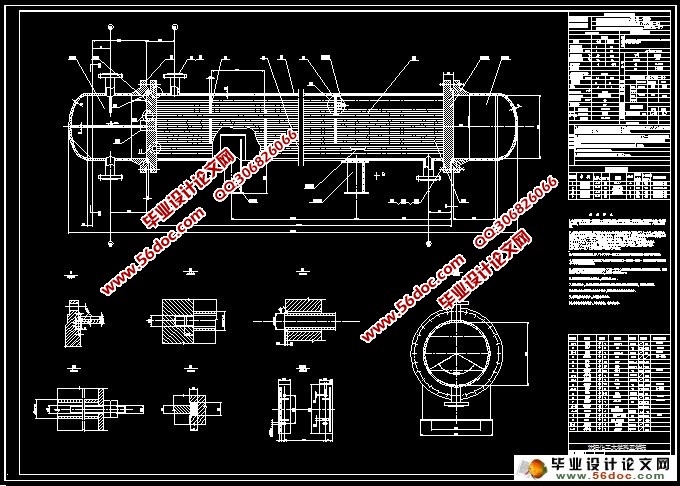

固定管板式换热器由管箱、壳体、管板、管子等零部件组成,其结构较紧凑,排管较多,在相同直径下面积较大,制造较简单。

固定管板式换热器的结构特点是在壳体中设置有管束,管束两端用焊接或胀接的方法将管子固定在管板上,两端管板直接和壳体焊接在一起,壳程的进出口管直接焊在壳体上,管板外圆周和封头法兰用螺栓紧固,管程的进出口管直接和封头焊在一起,管束内根据换热管的长度设置了若干块折流板。这种换热器管程可以用隔板分成任何程数。[3]

换热器设计的优劣最终要看是否适用、经济、安全、运行灵活可靠、检修清理方便等等。一个传热效率高、紧凑、成本低、安全可靠的换热器的产生,要求在设计时精心考虑各种问题.准确的热力设计和计算,还要进行强度校核和符合要求的工艺制造水平。

为了按照要求设计固定管板式换热器的机械结构设计和绘图查阅GB151-1999《管壳式换热器》和GB150-2011《钢制压力容器》和GB和JB等标准。

主要的步骤有标准件的选用,各零件间连接结构的设计,零件材料的选择还有厚度的计算。其中包括了封头,筒体,管箱壁厚和管板的计算,稳定性校核和管子拉托力,支座,容器法兰,接管法兰,接管的选择以及管板与壳体之间连接结构的设计,换热器与管板之间连接结构设计,折流板,开孔补强设计。 随着经济的高速发展,我们便利的生活因有现有的科技成果有了质的飞跃,换热器的设计技术也在不停的更新换代,以后的设计前景和应用前景将会更加光明。

已知条件为:设计压力为管程1.1MPa,壳程0.88MPa,工作温度管程25℃,壳程175℃,设计温度管程180℃,壳程105℃,管程介质为1MPa的水,壳程介质为0.8MPa的水蒸气。依据给定条件所得传热面积为95m2。考虑到介质特性等因素,采用Φ25×2.5×3000的#20(材料)的无缝钢管,本设计采用410根换热管可满足换热量。设定拉杆数量为7根,计算得到筒体直径为DN=1000mm。完成了压降计算、强度计算、开孔补强、管箱短节壁厚计算等。在强度设计中,依据GB150进行筒体、封头强度设计及校核,依据流量进行入口接管、出口接管等管口直径的选择,依据等面积补强法进行开口补强计算。本设计选择管板延长兼做法兰,依据GB151中的弹性支撑假设对管板进行设计和校核,管板与换热管的连接方式为焊接,拉杆与管板为螺纹连接结构。

本设计充分的利用材料,适用比较多的场合。410根换热管更加体现了换热的效率。在同样的换热器中此换热器十分的廉价、安全。所以该换热器在工厂中占有重要位置。[4]

关键词: 换热器; 结构设计; 计算; 校核

Abstract

Tube shell type heat exchanger as fixed tube plate heat exchanger, a structure with a representative, is the more extensive application of a heat exchanger. This heat exchanger has many characteristics: simple structure, compact, wide range of application, high safety factor, a wide range of materials, low cost, heat exchanger surface cleaning is very convenient. Due to the fixed tube plate heat exchanger can withstand higher operating temperatures and pressures, so this kind of heat exchanger occupies a great advantage in all kinds of high temperature and high pressure anlarge heat exchanger.

Heat exchanger is a simple with different temperatures of two or more fluid between heat transfer equipment. In industrial production process, different kinds of heat exchange process, its main function is the heat transfer by the high temperature of the fluid to fluid temperature is low, the fluid temperature to process indicators, to meet the needs of the production process. In addition, heat exchanger and recovery of waste heat, waste heat, especially an effective device for low grade heat energy.

Fixed tube sheet heat exchanger composed of a tube box, shell, tube sheet, pipe and other parts, the structure is compact, discharge tube is more, in the same diameter area is larger, the manufacture is simple.

Fixed tube is the structural characteristics of plate heat exchanger tube bundle is arranged in the shell, welding or expansion joint method for both ends of the pipe bundle fixing pipes on the tube plate, at both ends of the tube plate directly and shell welded together, the import and export of the shell pipe is directly welded on the shell, plate outer circumference and sealing flange with bolts, the import and export of the tube side of the tube and head directly welded together, in the tube bundle according to the length of the heat exchange tube is set a plurality of folded plate. The heat exchanger tube side can be used in any way is divided into several partitions.

For the pros and cons of heat exchanger design ultimately depends on whether the application, economic, security, reliable and flexible operation, maintenance is convenient to clean, and so on. A heat transfer efficiency high, compact, low cost, safe and reliable for heat exchanger produced, requirements in design carefully consider all kinds of problems. Accurate thermal design and calculation, but also for strength check and conform to the requirements of manufacturing process levels.

In order to in accordance with the requirements of the design of fixed tube plate heat exchanger, mechanical structure design and drawing of access to GB151-1999< tube shell heat exchanger heat exchanger > and GB150-2011< steel pressure container > and GB and JB standard.

Standard parts of the selection of the main steps, design of connecting structure between the parts, parts and materials selection and calculation of thickness. Including the head, cylinder, the calculation of tank wall thickness and tube plate tube, stability check and pipe rato force, support, pressure vessel flange, took over the flange, took over the selection and the tube plate and the shell is connected between the structure design, heat exchangers and pipe plate is connected between the structure design, baffled, opening reinforcement design.

With the rapid development of economy, convenience of our life because of the existing achievement of science and technology has been a qualitative leap, for heat exchanger design technology is also in constantly upgrading, the future prospects of design and application prospects will be brighter.

Short . rod meet the change ( to consider . income on the basis of the Cheng, Cheng Cheng, pipe, tube, Cheng, as known condition: the design pressure for tube side shell working temperature range shell design temperature range shell tube medium water shell medium water vapor. The given conditions the heat transfer area of the medium characteristic factors, the diameter of 25 x 2.5 x 3000 materials) seamless steel tube, the design of the heat pipes heat. Set number is 7, the calculated cylinder diameter of the pressure drop calculation, strength calculation, opening reinforcement, tube box wall thickness calculation. In the strength design, according to cylinder head strength of Design and verification, according to the flow of inlet pipe, outlet nozzle and orifice diameter selection, based on area method of reinforcement of ringent strength calculation. The tubesheet extended as flange concurrently, according to the elastic support hypothesis of tube sheet design and verification, the tube plate and the heat exchange tube and the connection mode of welding, the pull rod and the tube plate is threaded connection structure.

The design of full use of materials, for more occasions.410 root tube shows that the heat transfer efficiency of heat exchange. In the same for heat exchanger in the heat exchanger is very cheap. Security. Therefore, the change heat exchanger in the factory occupies an important position.

Key words: heat exchanger; structural design; calculation; check

目 录

第一章前言 1

1.1 换热器的介绍 1

1.2 固定管板式换热器的特点 1

1.3 换热器的未来发展趋势 2

第二章换热器传热工艺计算 4

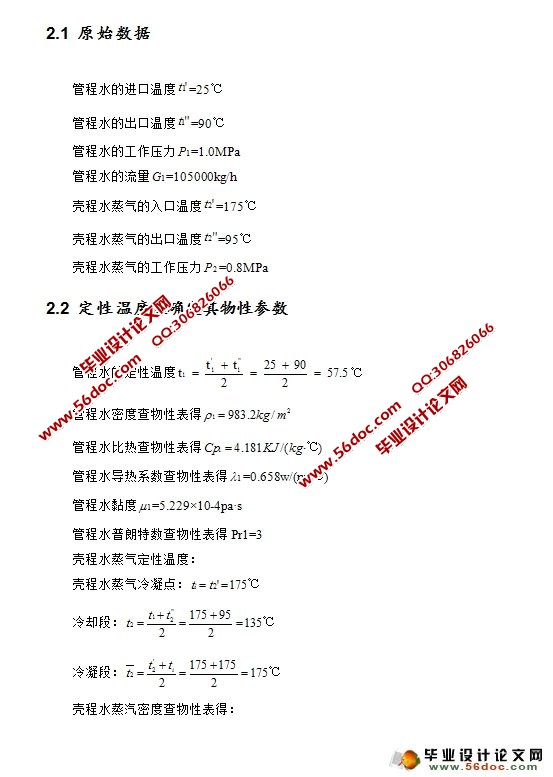

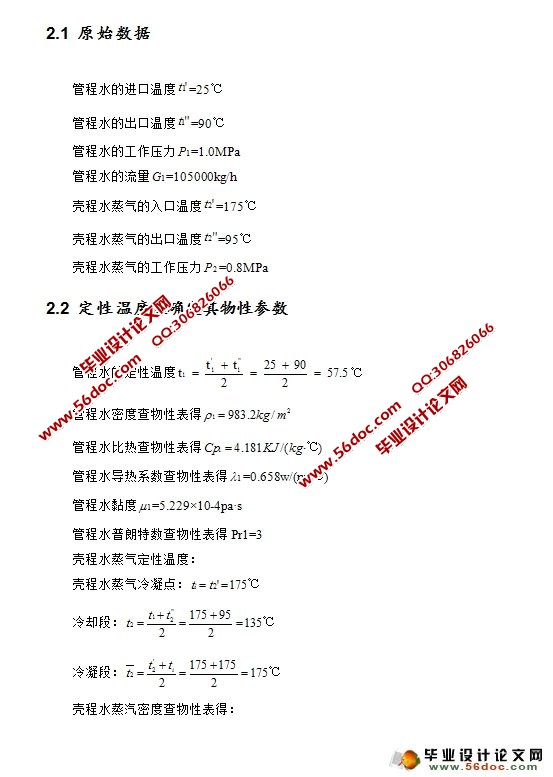

2.1原始数据 4

2.2定性温度及确定其物性参数 4

2.3传热量与水蒸气流量计算 5

2.4有效平均温差计算 6

2.5管程换热系数计算 7

2.6 结构的初步设计 8

2.7壳程换热系数计算 9

2.8 总传热系数计算 10

2.9 管壁温度计算 11

2.10 管程压力降计算 11

2.11 壳程压力降计算 12

第三章 固定管板式换热器结构设计计算 15

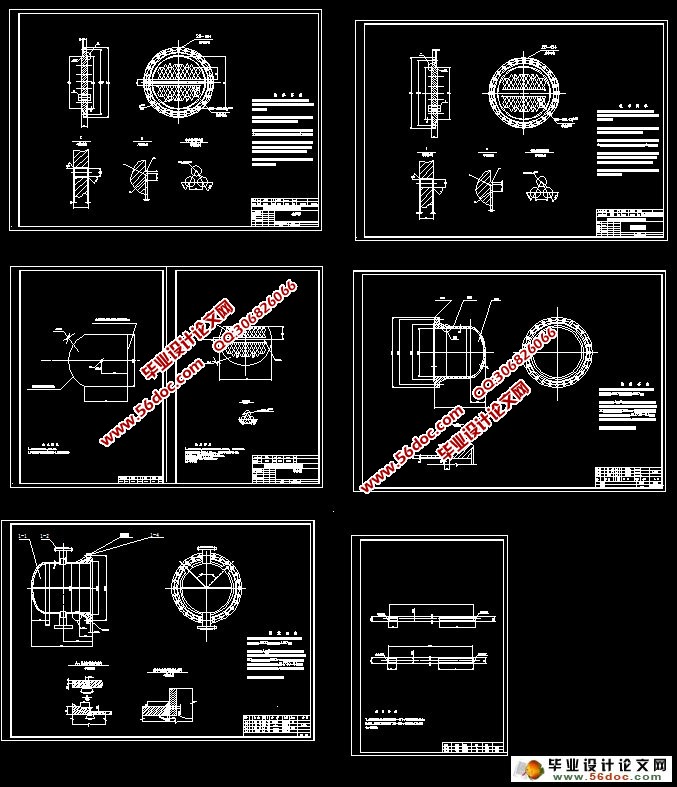

3.1 换热管材料及规格的选择和根数的确定 15

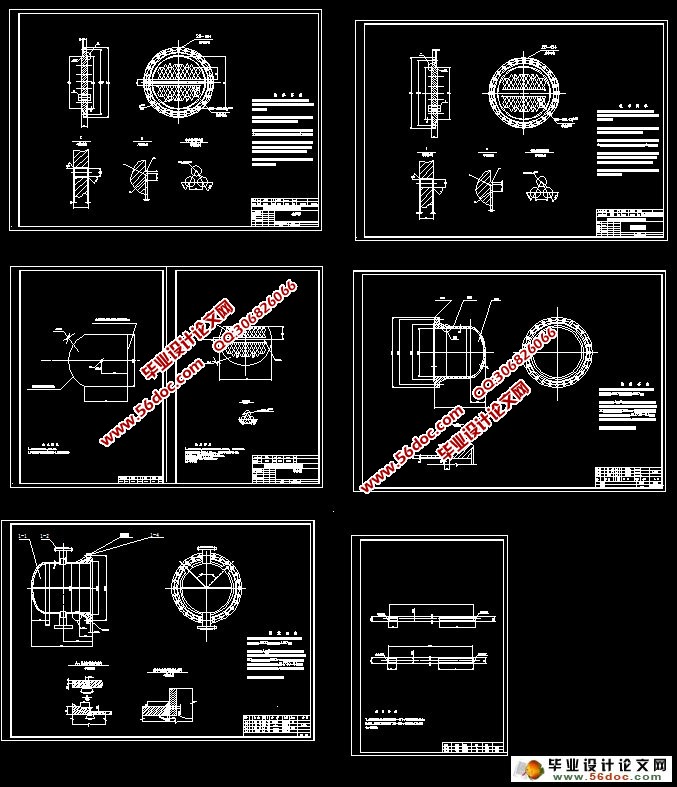

3.2 布管方式的选择 15

3.3 筒体内径的确定 16

3.4 筒体壁厚的确定 16

3.5 筒体水压试验 17

3.6 封头厚度的确定 17

3.7 管箱短节壁厚计算 18

3.8 管箱水压试验 19

3.9 管箱法兰的选择 19

3.10 管板尺寸的确定及强度计算 20

3.11 是否安装膨胀节的判定 32

3.12 防冲板尺寸的确定 32

3.13 折流板尺寸的确定 32

3.14 各管孔接管及其法兰的选择 33

3.15 开孔补强计算 38

3.16 支座的选择及应力校核 40

3.16.1 支座选择 40

3.16.2 鞍座的应力校核 41

参考文献 45

致谢 46

|