中药厂中药浸出液蒸发系统设计(含CAD零件装配图)(设计说明书12000字,CAD图纸5张)

摘要

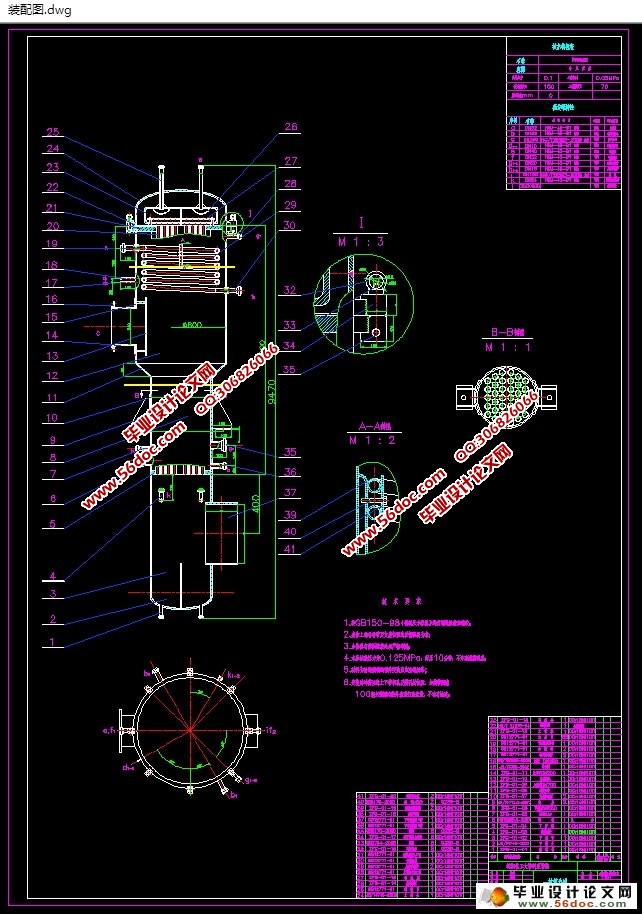

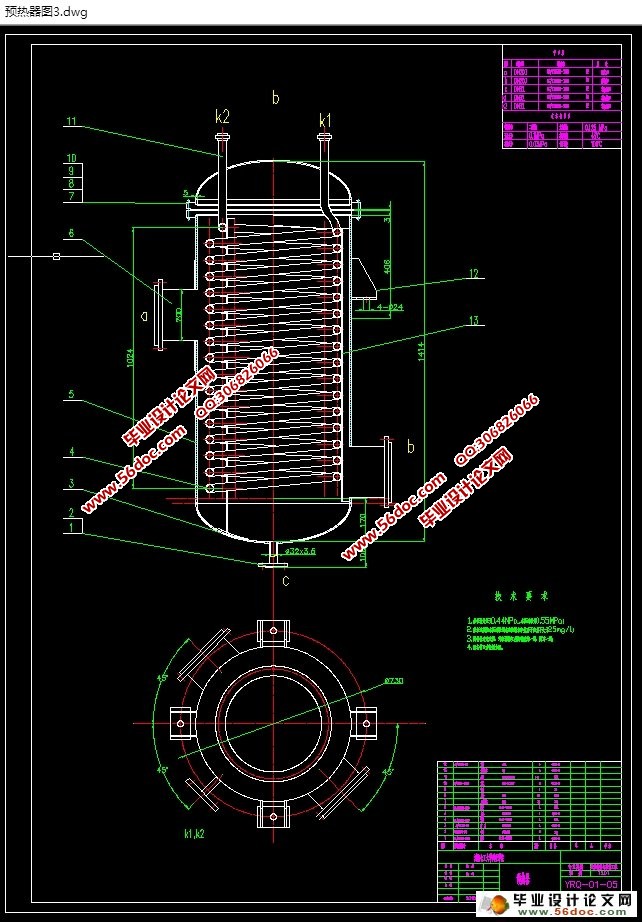

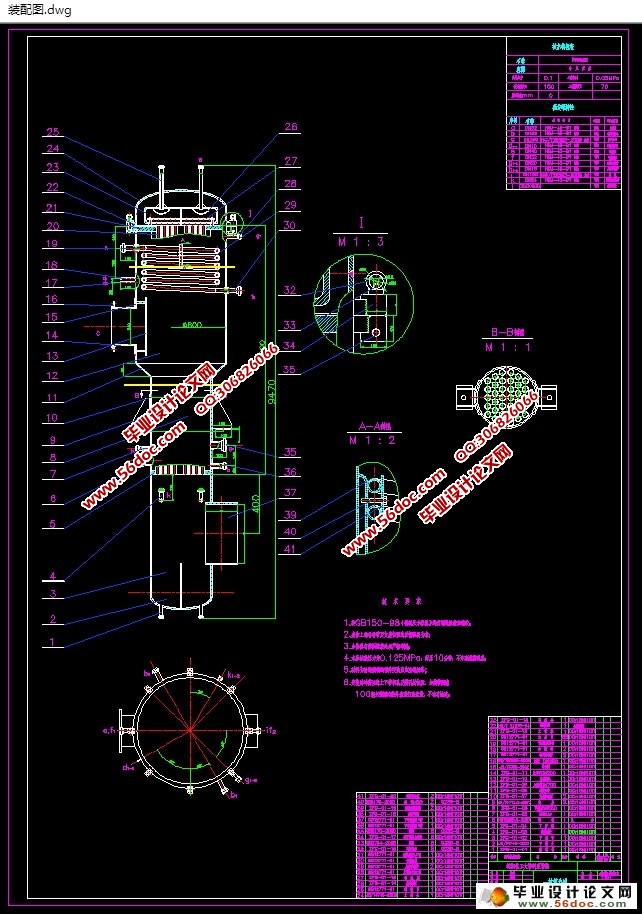

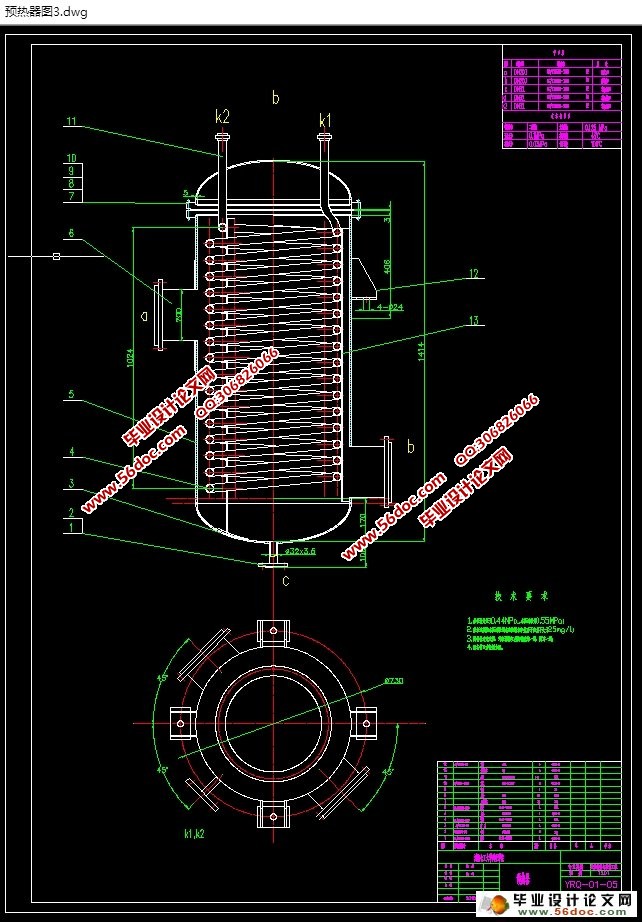

本设计是中草药行业处理2750Kg/h的中药厂中药浸出液蒸发系统设计,对系统的蒸发罐、分离器、热能压缩泵、预热器、冷凝器、离心泵、真空泵及其他附属设备进行设计,设计主要包括蒸发系统的特点及选择工艺流程、选题设计与论证、设计计算、技术经济分析、安装装备要求与安装调试注意事项等几大部分。其中设计计算包括物料衡算,热量衡算,热能压缩泵、预热器、管路、冷凝器、真空泵的设计与选择。本设备系统采用顺流进料,具有效率高、节能、物料预热温差小,有利于保证产品的质量、节能降耗、设备占地面积小、传热效果佳、运行效果、运行费用低、经济性高、便于操作,且能保证物料在蒸发过程中不变性等特点。其中有许多部分的设计借鉴了国内外的一些先进的理论和方法,以合理经济为设计准则,力争达到技术先进、质量达标、操作方便、能耗低及无污染的设计目标,此设计的优点是传热效果好、热能利用率高、生产效益高、已于制造。

由中药浸出液制浸膏的技术和装备还相当原始落后,蒸发器基本上沿用外循环升膜式蒸发器,浓缩收膏还广泛地采用带夹套敞口熬膏锅。由于中草药的成分复杂,如果蒸发加热温度过高和受热停留时间太长,易使部分热敏性成分在加热面上结焦。

以实验室蒸发装置现状看开发的要求为出发点,从确定蒸发系统的流程、实验装置中蒸发浓缩系统的组成、实 验装置的开发思路三方面探讨了中药浸提液蒸发实验装置的开发设计。所以在设计过程中要特别注意保留工业用大型蒸发装置的一般特点,在此基础上按比例缩小,这样完成一次实验所需要的中药浸提液量较小,从而满足了“省钱”的要求,同时, 测量精度要求较高。

中药浸提液浓缩的原理也是如此,即通过蒸汽加热使中药浸提液中的水分达到沸点脱离,而中药浸提液中的固形物以及其它物质总量保持不变,从而使中药浸提液的浓度增加,达到浓缩的目的。由于中药浸提液属于热敏性物料,为了保持产品的品质,需要在较低的温度下蒸发浓缩。所以,在工业生产中采用真空操作以降低溶液的沸点。 蒸发是一个传热过程,设备属于热交换器,因此蒸发设备与一般的传热设备并没有本质上的区别。但是,蒸发设备必须适应蒸发过程的特点,它除了具有进行传热的加热室以外,还要有足够的蒸发空间,以使二次蒸汽从溶液中分离出来,并使二次蒸汽中的液滴与雾沫尽可能完全地分离。蒸发器一般采用蒸汽作为加热介质,为提高传热效果,应使加热蒸汽均匀地分布,而冷凝液与蒸发过程产生的不凝性气体要及时排出。而且,溶液的特性(如粘滞性、发泡性、结晶性、结垢性、腐蚀性及热敏性等)对蒸发设备也提出了种种要求。

关键词;中草药; 三效; 蒸发系统; 浸出夜: 蒸发器

Abstract

This design is 2750 kg/h of Chinese herbal medicine industry, the traditional Chinese medicine factory of Chinese medicine leaching liquid evaporation system design of the system of evaporation cans, separator, heat compression pump, heater, condenser, centrifugal pumps, vacuum pumps and other auxiliary equipment design, the design mainly includes the characteristics of evaporation system and the selection process, subject design and demonstration, design calculations, technical and economic analysis, equipment installation requirements and installation and debugging matters needing attention and so much. Design calculation including material balance, heat balance, the compression heat pump, heater, pipe, condenser and vacuum pump design and selection. The equipment system adopts downstream feed with high efficiency, energy saving, material preheat temperature difference is small, to ensure the quality of products, saving energy and reducing consumption, equipment cover an area of an area small, good heat transfer effect, running effect, low operation cost, high efficiency, easy operation, and can guarantee invariance in the process of evaporation material, etc. Many of them part of the design of learning some advanced theories and methods of home and abroad, the design criterion of the economy as a reasonable, strive to achieve advanced technology, quality standard, convenient operation, low energy consumption and pollution-free design goals, this design has the advantage of good heat transfer effect, high heat energy utilization, high production efficiency, has been in manufacturing.

By leaching liquid extract of Chinese medicine technology and equipment are quite primitive, evaporator basically used outside the loop climbing film evaporator, concentrated extract is widely used for jacketed exposure paste pot. As the Chinese herbal medicine composition is complicated, if the evaporation heating temperature and heating time is too long, easy to make some heat-sensitive ingredients coking on the surface of the heat.

In laboratory evaporation device status see the demand of development as a starting point, from the process of evaporation system, the composition of evaporation and concentration system experiment device, the real thinking on the development of the test rig three aspects discusses the development of Chinese medicine leaching liquid evaporation experiment device is designed. So in the design process to pay special attention to keep the general characteristics of large evaporation devices used in industry, on the basis of the scale, so need to complete a experiments of traditional Chinese medicine extract quantity is small, so as to meet the requirements of the \"save\", at the same time, the measuring accuracy is higher.

So is a Chinese traditional medicine the principle of leaching solution concentration, namely by steam heating water reached the boiling point in the leaching solution from Chinese medicine, and traditional Chinese medicine extraction liquid solids and other material from the total amount remains the same, thus increase the concentration of extract of traditional Chinese medicine, to achieve the purpose of enrichment. Because Chinese medicine extract are heat-sensitive materials, in order to maintain the quality of products, need to evaporation concentration at lower temperatures. So, the vacuum operation is applied in the industrial production to reduce the boiling point of the solution. Evaporation is a heat transfer process, equipment belong to the heat exchanger, thus evaporation equipment and general there is essentially no difference between heat transfer equipment. Evaporation equipment, however, must adapt to the characteristics of evaporation process, it besides has on heat transfer of the heating chamber, evaporation have enough space, separated from a solution to make the secondary steam, and the secondary droplets in steam and entrainment separation as completely as possible. Evaporator generally using steam as a heating medium, to improve the heat transfer effect, should be evenly distributed, make the heating steam and condensate and evaporation process of no non-condensable gas discharge in time. And the characteristics of the solution (such as viscosity, foaming, crystalline, scaling, corrosion and heat sensitive, etc.) of evaporation equipment are also put forward various demands.

Keywords: Chinese herbal medicine; Three way; Evaporation system; Leaching night: evaporator

本设计为节能型中药厂中药浸出液蒸发系统设计,蒸发水量2750kg/h。技术参数;为中药浸出液初始温度为15℃,初始固形物含量为0.05%,浓缩终了固形物含量为35%。设计效数为三效,料液经预热器预热后,通过盘管预热,热压泵抽二效汁气作为一效热源。

目 录

第一章绪论 1

1.1 中药产业的发展现状 1

1.2 设计内容及采取方法 2

1.2.1设计内容 2

1.2.2采取方法 2

第二章蒸发技术 3

2.1蒸发技术 3

2.2降膜蒸发器 3

2.3三效降膜蒸发器的特点 4

2.4多效降膜式蒸发器的特点 5

第三章工艺计算 6

3.1物料衡算 6

3.1.1蒸发水量 6

3.1.2热压泵的喷射系数 6

3.2热量衡算 7

3.2.1一效蒸发罐的热量衡算 7

3.2.2二效蒸发罐的热量衡算 8

3.2.3三效蒸发罐的热量衡算 9

3.2.4总热量衡算 10

3.3蒸发罐设计计算 11

3.3.1各效蒸发罐设计 11

3.3.2周边流量校核 12

3.3.3.蒸发罐筒体内径 14

3.3.4蒸发罐壁厚校核 15

3.4各效预热盘管的设计计算 19

3.4.1一效预热盘管 19

3.4.2二效预热盘管 20

3.4.3三效预热盘管 21

3.4.4筒体封头的设计 22

3.5分离器直径和高度的设计 23

3.5.1分离器直径 23

3.5.2分离室高度 24

3.5.3分离器壁厚设计 24

3.5.4分离器封头的设计 25

3.6热能压缩泵的设计 26

3.6.1拉伐尔喷嘴的计算 26

3.6.2泵体的基本尺寸 27

3.6.3扩压室的设计计算 28

3.7预热器的设计 29

3.8冷凝器的设计 30

3.8.1热量 30

3.8.2冷凝器所需冷却的热量 31

3.8.3冷凝器的结构设计 31

3.8.4冷凝器封头 31

3.8.5冷凝器壁厚校核 31

3.9管路设计计算 32

3.9.1蒸汽矩形管道设计 32

3.9.2物料管设计 33

3.9.3上、下不凝气管 34

3.9.4冷凝水出口管 34

3.10泵的设计与选择 35

3.10.1离心泵的设计与选择 35

3.10.2真空泵的选择与设计 35

3.11 CIP局部清洗系统 36

第四章安装前的准备要求与安装注意事项 37

结论 38

致谢 39

参考文献 40

附录工艺流程图 41

|